Internal Pipecoater-III/125

Internal Pipecoater for pipe ID 76 mm to 125 mm (3” – 5”)

PIPECOATER-III/125 tool is designed to coat the inside of pipe or tubing ranging from 76 to 125 mm (3” – 5”) ID without the need to rotate pipe or tubing and to apply an even paint film thickness throughout. Generally, any type of coating may be used in this tool that can be airless sprayed.

Do you have questions about how we can help your company? Send us an email and we’ll get in touch shortly.

- More than 50 years of experience

- Airblast offices in 12 countries

Product description

PIPECOATER-III/125 tool can be connected to a suitable airless paint spray machine of minimum 45:1 ratio. The unit is connected to the end of a pipe lance and connected to the high pressure paint hose coming from the spray pump. An air hose is required to connect to the PIPECOATER-III/125 as well. Once the PIPECOATER-III/125 is positioned within the pipe or tubing, regulate the paint and air flow to the correct pressure. The spray gun is triggered to begin the paint flow. The paint will be sprayed through a spin nozzle controlled by the air flow in a 360° spraying pattern.

To stop the PIPECOATER-III/125, release the spray gun trigger and shut off the air supply to the unit. For the best possible result, one man should operate the spray gun while another man pulls the tool through the pipe or tubing.

Advantages

- Efficiently handles wide range of coatings

- Applies uniform layer at remarkable speed

- No need to rotate the pipe or tubing

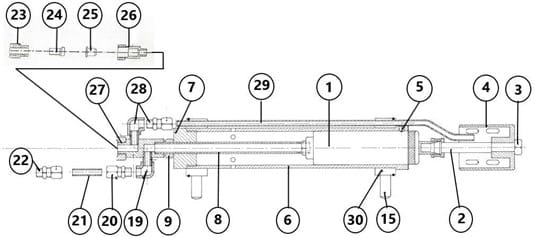

PIPECOATER-III/125 Internal pipecoater assembly

PIPECOATER-III range are economy models, developed for pipe or tubing ranging from 76 mm to 900 mm (3” – 36”) ID. The three models are executed with different centering devices which must be set to the right diameter manually.

| Part no. | Description |

| 7301001 | PIPECOATER-III/125 complete unit with centering carriage. For pipes with ID of 76 mm to 125 mm (3” – 5”) |

PIPECOATER-III/125 Spare parts

| Item | Part no. | Description |

| 1 | 7310000 | Air motor |

| 2 | 7310100 | Axle |

| 3 | 7310200 | Nut M10 |

| 4 | 7310300 | Rotating head dia 54 mm |

| 5 | 7310400 | Bolt M6 x 8 |

| 6 | 7310500 | Aluminium housing |

| 7 | 7310600 | Rear end plate |

| 8 | 7310700 | Air tube ¼” x 170 mm |

| 9 | 7310800 | Nut ¼” x 8 mm |

| 15 | 7315600 | Centering button 4.5 mm |

| 3007000 | Centering button 8 mm | |

| 3008000 | Centering button 15 mm | |

| 3009000 | Centering button 20 mm | |

| 3010000 | Centering button 28 mm | |

| 16 | 3010100 | Bolt M6 |

| 18 | 3010200 | Locking bolt M10 |

| 19 | 7315700 | Elbow ⅛” x ⅛” MF |

| 20 | 7315800 | Coupling ⅛” x dia 6 mm |

| 21 | 7315900 | PU Hose dia 6 – 8 / 15 cm |

| 22 | 7316000 | Coupling ¼” x dia 6 mm |

| 23 | 7314500 | Filter holder |

| 24 | 7314600 | Tip filter 100 mesh (standard) |

| 7314650 | Tip filter 60 mesh | |

| 25 | 7315000 | Flow control tip 0.042” orifice (standard) |

| 7315100 | Flow control tip 0.020” orifice | |

| 7315200 | Flow control tip 0.028” orifice | |

| 7315300 | Flow control tip 0.060” orifice | |

| 7315400 | Flow control tip 0.064” orifice | |

| 7315500 | Flow control tip 0.076” orifice | |

| 26 | 7314700 | Tip holder |

| 27 | 7316100 | Inlet housing ⅛” x ¼” |

| 28 | 7316200 | Elbow dia 6 – ⅛” |

| 29 | 7316300 | Paint tube dia 4 – dia 6 |

| 30 | 7316400 | Centering collar dia 48 mm |