Tip #8 - Abrasive Operating Mix

The Operating Mix is the mixture of recyclable abrasive particles used for blasting. It is characterized by it’s size distribution.

1. Importance of the operating mix

The particles having undergone various degrees of wear, the size distribution of the operating mix is very different from that of new abrasive although it has the same nominal size:

The average particle dimension in the Operating Mix being lower than in the new product, the number of particles per kg and therefore the number of impacts per minute and the coverage rate are higher.

As the abrasive is used for blasting the particles gradually wear - the size distribution of the operating mix is therefore very different from that of new abrasive although it has the same nominal size:

The average particle dimension in the Operating Mix is smaller than in new abrasive - the number of particles per kg, and therefore the number of impacts per minute and the coverage rate, are higher.

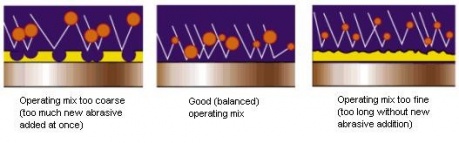

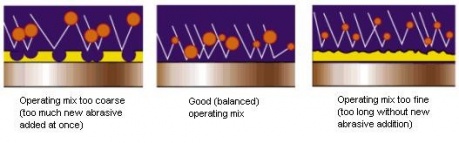

2. Change in operating mix

The abrasive particles in the Operating Mix gradually wear down and eventually become small enough to be extracted by the separator – the size at which particles are removed can be adjusted by the separator setting. The size distribution of the Operating Mix is a determining factor of the quality of the treatment – the Operating Mix has therefore to be checked regularly and kept constant.

To keep the Operating Mix as constant as possible the hopper has to be kept full of new abrasive - the new product must be added regularly and should not exceed 10% of the total capacity of the machine.

Download PDF to read more: