Steel grit

High Carbon Steel Shot & Grit

Airblast has its own production line for high quality steel grit abrasive with an excellent durability. In our warehouse we keep an extensive stock of steel shot and steel grit.

Steel grit is a very cost economic blasting media in shot blasting machines and blast rooms, because it can be recycled many times. There are three different hardness’, steel grit GP, steel grit GL and steel grit GH.

Steel grit blasting in surface preparation is used for cleaning rust, old coating layers and creating an anchor profile for the coating system to adhere. Steel grit blasting media are also used to remove mill scale and in the foundry industry for removal of the sand from the work pieces.

Do you have questions about how we can help your company? Send us an email and we’ll get in touch shortly.

- More than 50 years of experience

- Airblast offices in 12 countries

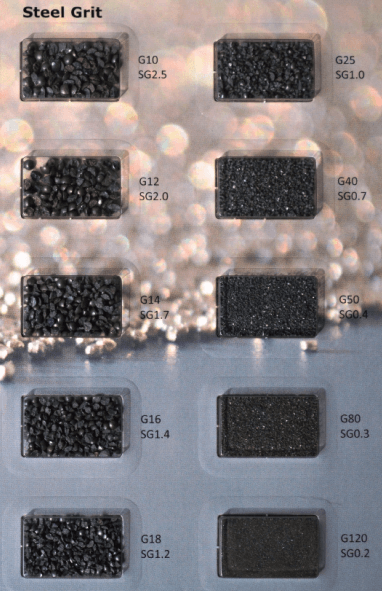

Grain sizes

| Product | Size range |

| Steel grit GH12 / GL12 / GP12 | 1,70 – 2,40 mm |

| Steel grit GH14 / GL14 / GP14 | 1,40 – 2,00 mm |

| Steel grit GH16 / GL16 / GP16 | 1,00 – 1,70 mm |

| Steel grit GH18 / GL18 / GP18 | 0,70 – 1,40 mm |

| Steel grit GH25 / GL25 / GP25 | 0,40 – 1,20 mm |

| Steel grit GH40 / GL40 / GP40 | 0,30 – 1,00 mm |

| Steel grit GH50 / GL50 / GP50 | 0,20 – 0,70 mm |

| Steel grit GH80 / GL80 / GP80 | 0,10 – 0,40 mm |

| Steel grit GH120 / GL120 / GP120 | 0,10 – 0,30 mm |

Specifications

| Chemical composition | (C): 0.80 – 1.20% | (Mn): 0.60 – 1.20% | (Si): ≥ 0.40 | (S): ≤ 0.05% | (P): ≤ 0.05% |

| Hardness | GP: 42 – 52HRC, GL: 53 – 60HRC, GH: 60 – 64HRC | ||||

| Hardness deviation | Max. deviation ±3.0 HRC | ||||

| Microstructure | Tempered martensite or sorbite | ||||

| Density | 7.6 g/cm³ | ||||

| Bulk density | 4.2 g/cm³ | ||||

Application

| Steel Grit | Application |

| G10/SG2.5 G12/SG2.0 | Sand removal of large sized castings, scale removal of large sized products from forging, stamping, dieforging, drawing and rolling or after heat treatment (e.g. pipes, sections, plates, fittings, wire). |

| G16/SG1.4 G14/SG1.7 | Sand removal of large and medium sized castings, scale removal of forging and heat-treated work pieces, surface blast cleaning of steel plates, sections and steel structures, shot peening of work pieces, cutting of granite. |

| G18/SG1.2 G25/SG1.0 | Sand removal of medium and small sized castings, surface blast cleaning of forgings, heat-treated pieces, steel pipes, sections and steel structures, surface treatment before painting, shot peening of work pieces. |

| G25/SG1.0 G40/SG0.7 | Surface blast cleaning of small sized castings, forgings and heat-treated pieces, aluminium and copper alloy castings, steel plates, steel pipes, sections and steel structures, shot peening of work pieces. |

| G50/SG0.4 G80/SG0.3 G120/SG0.2 | Surface blast cleaning of stainless steel plates, thin steel plates, non ferrous alloys, dacromet coat. |

Steel grit Applications

Our steel grit abrasives are cost efficient due to the duribility and because recycling is possible. Due to long extremely long life time, savings are made on abrasive cost itself, but also on disposal costs.

Blast rooms

In blast rooms mainly our steel grit GH is used. This is the hardest and most aggressive abrasive available (60-64 HRC). Because compressed air and personal are expensive, it is favorable to use this product, because it has the quickest cleaning action.

In blast rooms this is used to remove old coatings, rust and mill scale. It is ideal for surface preparion and creating and anchor profile prior to coating, metalisation or powder coating. Our GH25, GH40, GH50 and GH80 are very often used in blast rooms. In case a very deep anchor profile is required of Rz > 120 um, the GH18 and GH16 can be considered.

Wheel Blast Machines

In shot blasting machines, mainly the softest steel grit GP is used (42-52 HRC). Steel grit GP is also referred to as angular shot, because it starts off angular but becomes round after some cycles in the wheel blast machine. When a more angular surface profile is required, steel grit GL (53-60 HRC) can also be used, for example when metallization follows after the blasting process. Not every wheel blast machine is suitable to work with the more aggressive GL hardness. This type of abrasive may never be used in wheel blast machines, because it will be brutal on the wear parts and inside of the machine.

In wheel blast machines steel grit is used for the removal of mill scale, rust, old coating layers on steel plates, steel beams and small steel parts. Steel grit is also used for deburring of metal parts and in the foundry industry the steel grit GP can be used for desanding of the foundry parts. Larger parts require a larger size abrasive.

Sometimes steel grit GP is added to work mix of shot to get some extra profile and aggressiveness to the blasting process.

Blast Cabinets

In pressure blast cabinets steel grit of GH hardness can be used, normally a finer grain size. Vacuum injection blast cabinets are not suitable, because the specific weight of this abrasive is too high for this blasting method.

Vacuum Blasting Machines

In strong vacuum blasting machines like the AB1070, this product can be used. Normally, the grain size GH40 or GH25 is suitable for this application.