Each Airblast Blast room is designed specifically on a project by project basis and the possibilities for customization are endless.

- In house engineering and production

- World-wide project experience

- Standard and custom designed systems

Blast Rooms for industrial scale surface preparation

Blast rooms represent the highest tier of abrasive blasting infrastructure, providing spacious, purpose-built environments where large components and structures can undergo comprehensive surface treatment. These specialized facilities have transformed how industries approach large-scale blasting projects. This offers a combination of efficiency, safety, and environmental control that’s impossible to achieve with portable equipment or smaller enclosures.

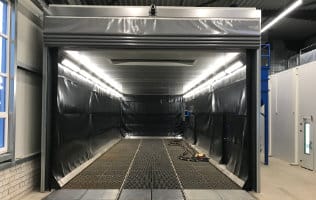

Modern blast rooms combine robust construction with advanced engineering to handle the demanding nature of high-volume abrasive blasting. The walls, typically made of specialized materials like manganese steel or reinforced panels, withstand the continuous impact of ricocheting abrasive media while containing noise and dust. Floors incorporate recovery systems that automatically collect, clean, and recycle abrasive materials, significantly reducing operational costs compared to outdoor or makeshift blasting areas.

Key Components of an Effective Blast Room

A well-designed blast room is more than just an enclosed space. It incorporates several critical systems that work together:

The filter system creates negative pressure inside the room, preventing dust from escaping while continuously filtering the air to maintain visibility and breathability. This system often includes multi-stage filtration that can capture particles down to micron-level sizes before releasing air back into the environment.

Lighting systems use specialized fixtures positioned to eliminate shadows and dark spots, helping operators maintain consistent quality across all surfaces. These lights are protected from abrasive impact and designed to deliver high-intensity illumination that cuts through dust.

Media recovery systems represent perhaps the most significant technological advancement in modern blast rooms. These systems automatically collect spent abrasive from the floor, transport it to cleaning stations where contaminants are removed, and then return usable media to the blast pot for reuse. This automation dramatically reduces material costs while minimizing downtime between blasting sessions.

Operator stations provide blast technicians with all necessary controls in an ergonomic layout, allowing them to adjust pressure, media flow, and other parameters without interrupting their work. Advanced rooms include computer interfaces that monitor and record blasting parameters to ensure process consistency and quality control.

Engineered blast systems

After an extensive investigation and analysis of the objectives and goals of the blast room our team of engineers draw upon years of experience and a long established installed base of blast rooms in operation around the world to ensure that the Airblast Blast Room proposal satisfies all of the criteria as well as allowing opportunities for future development.

As each Airblast Blast Room is designed specifically on a project by project basis the possibilities for customization are endless: multiple blasters operating on one room; product access through one end or both ends of the blast room; abrasive recovery options including: sweeping pit, cross conveyor, U shape, H shape, and complete floor automatic recovery with conveyor system or scrappers; down draft or cross draft dust extraction; automatic grit recycling incorporating magnetic separation.

For additional flexibility Airblast can provide a combined blast and paint room: once the blasting is completed and the abrasive recovered a separate paint extraction system is activated and painting of the product can begin. The reduced product handling provides additional quality control benefits as well as cost savings.

Airblast has an extensive reference list of installed blast rooms around the world working with companies such as Keppel Fells Singapore, Gdansk Shipyard in Poland, and many others.