Wet blasting is a surface cleaning and finishing process that uses a slurry of water and abrasive media propelled by compressed air to clean, debur, polish.

What is wet abrasive blasting and how does it work?

Wet abrasive blasting is surface preparation technique that combines water with abrasive materials to clean, descale, or prepare surfaces for coating. It is often used in façade cleaning, removal of graffiti and soft cleaning monuments. Wet abrasive blasting involves mixing water with abrasive particles and propelling the mixture at high or low velocity to remove coatings, rust, contaminants, graffiti and other surface imperfections. Unlike traditional dry sandblasting, wet abrasive blasting minimizes dust, which is the main advantage. On the downside it is slower than traditional dry blasting and doesn’t create as deep a surface profile.

Water is introduced into the blasting process, either at the nozzle or within the blasting system. The water dampens the abrasive, reducing dust and making the process safer. Various abrasives, such as garnet, aluminum silicate, calcium silicate, glass granules, glass beads, can be used depending on the application.

Wet abrasive blasting on steel will create flash rust on the surface because of the water, in this case an inhibitor must be used to prevent this.

Types of Wet Abrasive Blasting Techniques

Slurry Blasting

Abrasives and water are mixed in the blast pot to create a sludge or slurry. This slurry travels through the system by a hydraulic water pump and into a compressed air-stream. Normally the ratio is 75% blasting media and 25 % water and the maximum pressure when using the Aquastorm is 10 bars. The advantages of wet slurry blasting are:

- Dust production is reduced by 95%, so minimal or no containment required

- Longer hose length possible, also vertically

- Less consumption of abrasive.

- Less wear on nozzle and hose.

- Effective in situations where sparks or static electricity are a concern. In petrochemical industry for example.

- Sensitive blasting possible in for example façade or monument cleaning.

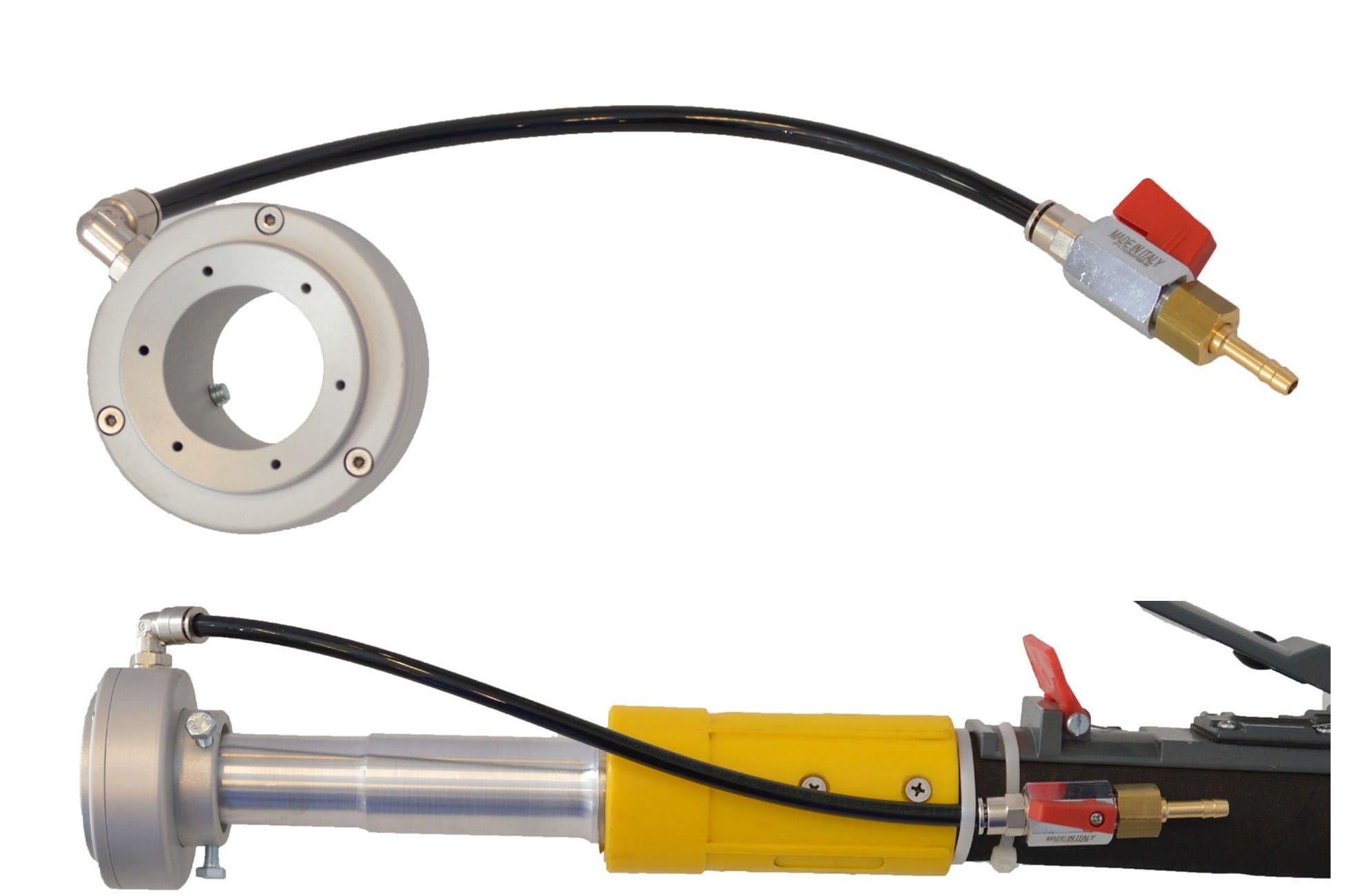

Water attachments

Slurry blasting is the most efficient way of wet abrasive blasting, but requires some investment in the equipment. There are also nozzles available which are a very accessible alternative and can easily be used with the existing dry blasting equipment.

A water injection nozzle adds water to the air stream at the nozzle. It can be connected with a normal garden hose and the amount of water added to the stream can easily be regulated with a simple valve. It greatly reduces the dust generated.

Another low budget option is a water attachment to the normal blast nozzle. This wet blast attachment creates a ring of water around the abrasive blast stream, effectively eliminating about 80% of the dust generated.

Vapor blasting

When Vapour blasting, the pressurized air is added to the water in the nozzle to create a mist or vapour. This leads to a process that is even milder than normal wet blasting allowing very gently cleaning. It is rather sophisticated technique that is typically performed in a blast cabinet. It is possible to degrease and blast products at the time and since it is a closed circuit, the abrasives can be reused. The abrasives that are used are normally finer.

(Ultra) High Pressure Water Blasting

Although not using abrasives, it is worth mentioning. High pressure water blasting is a technique which produces a high velocity stream of water by passing a flow of pressurized water through a specially designed small orifice nozzle. This jet has some erosive force and has been utilized for removing paints and corrosion products from structural steel. The pressure is very high (400 to 2800 bar), making it rather dangerous work for the operator.

High pressure water blasting without abrasives has not shown the capability of removing tight rust or intact mill scale from steel except at exceedingly slow rates or at ultra high pressures. In addition, it cannot produce an anchor profile (surface roughening) of the steel itself. In order to introduce additional erosive force into water blasting, abrasives must be incorporated into the water jet.

Conclusion

It is universally acknowledged that dry abrasive blasting is the most efficient and economical technique for cleaning structural steel for painting in industrial applications. The abrasive blasting unit delivers to the surface a high velocity stream of hard, angular abrasive, which has the ability to rapidly remove existing paints, rust, and millscale to roughen the base metal for improved adhesion. The equipment and techniques for dry blasting have become fairly well standardized and provide a high degree of reliability. Dry abrasive blasting is considerably faster than wet abrasive blasting.